Fire Water Monitor Specifications – What Features Should You Look For In A Fire Water Monitor?

If you are looking for a fire water monitor, you need to know its specifications. The following article will explain what features should be considered before purchasing a fire water monitor.

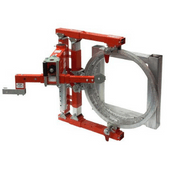

What is a Fire Water Monitor

A fire monitor is a fire fighting device used to project large quantities of water on to the risk area from a distance. Monitors are designed for different rated discharge capacities and can be operated manually or automatically.

What are the parts of a Fire Water Monitor

The monitor shall consist of following components:

- Base flange

- Reducer — wherever applicable

- Water barrel of seamless pipe

- Elbow 90° and 45°

- Swivel joint for horizontal and vertical rotation

- Lock handles for horizontal and vertical rotation

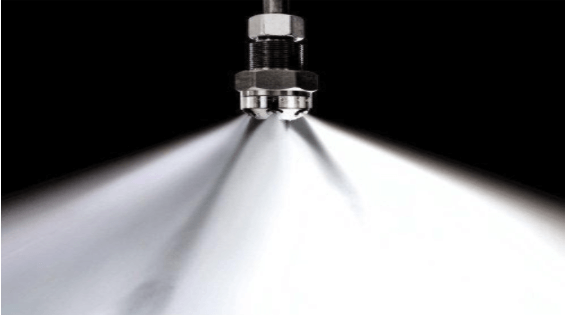

- Nozzle

- Handle or worm and worm wheel to facilitate vertical rotation,

- Drain valve.

Specifications to look for in a Fire Water Monitor

Material:

What kind of material is your monitor made from? Is it made with stainless steel, copper alloy, or stainless steel? Make sure that the material is appropriate for the environment where you’ll be using your monitor. For example, if you’re using your monitor aboard a ship or in an area where corrosion is likely to occur, then you should choose a monitor with a stainless-steel body.

Construction:

What kind of design does it have? The construction of monitor shall be welded, screwed or flanged. Monitor shall have the flange of diameter corresponding to stand post, that is, 63 mm, 75 mm and 100 mm respectively. Flanges of higher size may be used for better hydraulic efficiency and in that case it shall be welded with reducer. Traversing mechanism shall be provided to facilitate the horizontal and vertical rotation of monitor. This shall be either single handle bar type or worm and worm wheel type. Positive locks shall be provided for unattended operation. In case of worm and worm wheel geared unit, it shall be self locklng type. Drain valve shall be fitted above inlet flange to drain water from water barrel after usage.

Workmanship and Finish:

The complete assembly shall be of good workmanship and finish and free from burrs and sharp edges. Particularly, waterway shall have smooth finish.

Anti-Corrosive treatment:

All steel components subject to direct water contact shall be hot dip galvanized after fabrication to a minimum thickness of 0.03 mm. The aluminium parts subject to direct water contact shaIl be hard anodized to a minimum thickness of 0.015 mm. The thickness of galvanizing shall be measured with suitable thickness measuring meter.

Painting:

Monitor shall be painted with fire red or post office red colour conforming to shade No. 536 or 538 of IS 5. The paint shall conform to IS 2932

Performance Requirements:

It shall have minimum discharge capacity and horizontal throw specified based on type

For Water Monitor it shall be minimum

- 1750 lpm capacity , 53m horizontal throw

- 2580 lpm capacity, 60 m horizontal throw

- 3500 lpm capacity, 64 m horizontal throw

For Foam Cum Water Monitor it shall be minimum as below along with foam

- 1750 lpm capacity , 45m horizontal throw

- 2580 lpm capacity, 50m horizontal throw

- 3500 lpm capacity, 55 m horizontal throw

Leakage test:

The entire assembly shall be hydraulically tested to a pressure of 2.3N/mmz for 5 min and there shall not be any leakage

Marking :

Each monitor shall be clearly and permanently marked with the following:

- Manufacturer’s name and his trade-mark,

- Year of manufacture, and

- Discharge capacity, in lpm

Certification:

Monitor shall be certified to relevant standards such as BIS , EN or NFPA. Additionally, it may have suitable listings such as UL or FM as desired.

BIS standard for fire water monitors include

- IS 8442:2008 – Stand post type water and foam monitor for firefighting and

- IS 15811:2008 Long range water cum foam monitor with self-inducting, aspirating and non-aspirating jet and spray /fog nozzle for firefighting

Different Types of Fire Water Monitors Based on application

Water and Foam Monitors

There are two main types of fire water monitors: solid jet water monitors and foam monitors. Solid jet monitors are the most common type and they work by projecting high-pressure streams of water directly at the fire to extinguish it. Some models have a changeable nozzle head, so you can choose between a wide spray pattern or a narrow jet, depending on what’s most effective for your application.

Monitors with spray nozzles are used for critical locations such as process areas where fire fighters needed protection from high heat or potentially harmful vapors, but also need to be able to operate safely near the site of an oil refinery fire or chemical spill.

Foam monitors are required for storage tank farms, loading bays and other locations where there is a risk of oil spill and pool formation. They come with pick up tubes or built-in foam educators for foam induction.

Fixed, Portable, Vehicle mounted and Remote operated Fire Monitors

Firefighting monitors can also be further categorized into following types:

- Fixed type- installed permanently at one place.

- Portable type- can be carried from one place to another.

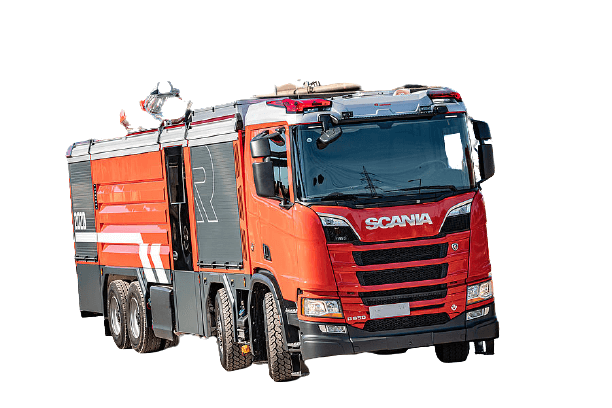

- Vehicle mounted type- mounted on a vehicle for firefighting operation

- Remote operated type- operated from a remote location as a separate unit or integrated with other equipment such as water supply sources, pumps etc.,

- Tower monitors- Installed over elevated structures for protection of towers, columns where ground monitors couldn’t reach

Conclusion

We hope you have found this article helpful. If you are still unsure about which fire water monitor is right for your needs, please ask us. We would be happy to assist with your enquiry and offer advice on getting the best value for money when it comes to purchasing new fire water monitors or upgrading existing ones.

Visit our Fire fighting monitors category page to discover a variety of options from the leading brands in the industry.

Hello Sir/Madam.

This is Mohammad from Sea Wide company.

I am glad to talk to you.

I am writing with regard to you that we are looking for spare parts for “FIRE MONITOR” with description below:

1) Max capacity : 1200 m3/h

2) Pressure class: PN16

3) Size : DN 150 mm

4) Standard flange : DIN 26333 FF

5) Weight : 200 kg

6) Azimuth sweep : 330 max

7) Elevation : -30+75

Please notice : it must be with Remote that we can control from long way.

I am looking forward to hearing from you.

Thanks for your consideration in advance.

Best wishes.

Please email your requirements to info@safetyproductfinder.com for a quick quote