Different Types of Fire fighting Nozzles Explained!

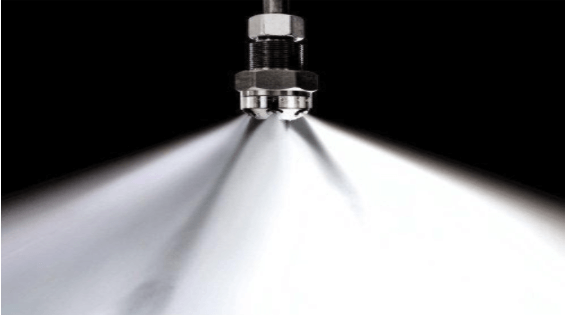

Fire fighting nozzles are one of the most important gears for firefighters to put out fires. A hand line nozzle is connected to the fire delivery hose to provide water flow to extinguish fires. Nozzles are designed to help put out fires by getting the right amount of water, in the right form, in the right place. Nozzles perform the following functions

- Control Flow of Water: The size of the orifice in the outlet of the nozzle controls the flow.

- Provide Reach: Restriction to flow of water created at the nozzle changes water pressure to velocity. Velocity provides the reach, which is necessary to get the water to fire spot.

- Create Shape: It helps to create a shape or pattern such as straight steam for penetration and wide angle fog spray for radiant heat protection.

The type of fire fighting nozzle we choose ensures effective fire extinguishing and better water flow.

Types of Fire Fighting Nozzles

There are five basic nozzle types:

1. Smooth or solid bore

The smooth or bore nozzle is the most basic of the five nozzle types, both in design and function. Its purpose is to produce a solid stream of water with large droplets, which provides maximum reach and penetration. The smooth bore is typically available as a tip or in a break-apart configuration

2. Fixed orifice or single gallonage

The fixed orifice nozzle, the simplest form of the combination or fog nozzle, provides flow at a predetermined rate of pressure that cannot be altered significantly while in use. However, when the nozzle pressure is varied, the flow varies either increasing or decreasing based on changes in the pump discharge pressure. Most of today’s fixed orifice nozzles can provide quality patterns even at reduced nozzle pressures as low as 50 psi. The fixed orifice is typically available as a nozzle, tip or in a break-apart configuration.

3. Selectable or Adjustable Gallonage

Selectable gallonage nozzles allow the nozzle operator to manually select a desired gallonage (flow) without shutting down. Like the fixed orifice nozzle, selectable gallonage nozzles can provide quality patterns even at reduced nozzle pressures. The selectable gallonage is typically available as a nozzle, tip or in a break-apart configuration

4. Automatic or constant pressure

An automatic nozzle is designed to maintain a relatively constant pressure over a wide range of flows. This is accomplished by a mechanical mechanism (typically a spring) in the nozzle that automatically adjusts to increase or decrease flow to maintain an outlet pressure, and thus provide optimum stream performance. It should be noted, that automatic nozzles when operated in low pressure conditions reduce flow in an effort to maintain optimum reach. The automatic is typically available as a nozzle, tip or in a break-apart configuration.

5. Multi-purpose nozzle

Multi-purpose nozzle is a combination smooth bore and fog nozzle, provides the maximum reach and penetration of a smooth bore, while still enabling the benefits of a fog stream at the same time or independently. This versatile type nozzle has the ability for large flows at reduced pressures, and is well suited for multiple applications: interior, exterior, and high rise attacks, CAFS systems, foam applications, direct and indirect attacks, cooling, protection, and ventilation. The multi-purpose is typically available as a nozzle.

Considerations in selection of Fire Fighting Nozzle

Type of fire fighting nozzle you choose shall be best suited for your application. The following information will help you determine which configurations are best for you.

What flow range is required?

Determine the minimum flow that will be required for you. Understand the maximum flow rate that can be achieved with normal pump pressures and hose layout. Decide whether the nozzle will always be used on the same hose or whether it will be used in other applications, which might require different flows.

Whether multiple patterns required?

Prior to choosing the nozzles, you’d better have in mind whether multiple patterns are needed, such as the fog mode and stream mode, or just a single pattern. Some fog nozzles have the same reach as the smooth bores at 7 bar. The fog pattern aims to protect on-duty firefighters from being hurt by extremely high temperatures particularly encountered at Industrial fires.

Who is controlling the flow and the availability of fire fighting manpower?

Reaction force is determined by the flow, nozzle pressure at the inlet and pattern. The more manpower available on the hose line, more flow and pressure can be physically handled for a longer period of time. If human resources are limited, considering nozzles with lower flows and/or reducing the rated pressure may help with firefighter fatigue.

If the nozzle operator should control the flow rate, an adjustable gallonage nozzle could be the best choice such as situations where the fire fighter is located far from the pump and communication is hard to maintain. If the pump operator is to control the flow rate, a single gallonage, an automatic nozzle or a multi-purpose nozzle would probably be the best.

What is the level of training?

Smooth bore nozzles require the least amount of training for the pump and the nozzle operator. Fog nozzle requires somewhat more training than smooth bore nozzle and the training shall include how to use various spray patterns characterized by a fog nozzle. A higher level training is required for the fire fighters and pump operator for using selectable gallonage and multipurpose fog nozzles and the personnel shall be conversant with the various flow settings and its advantage.

Click here to view our fire fighting nozzle collection to explore the variety of available nozzle options. After analyzing your needs and considering the strengths and purposes of each nozzle, you will be better prepared to choose how to spend your limited resources on the right combination of nozzles for your department.