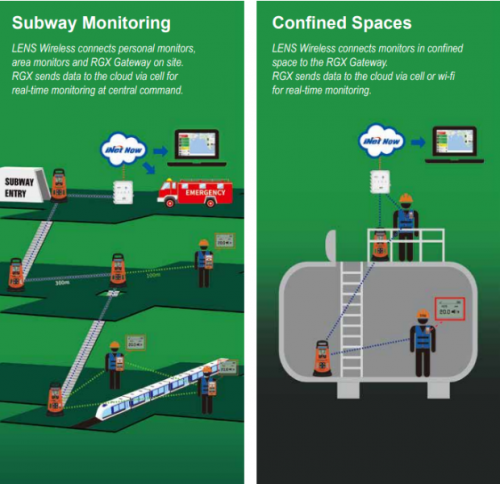

The emergence of Internet of things (IoT) technology has spurred operational transformation across numerous industries as it gives businesses the power to create backend infrastructure that supports data sharing. Connected safety software rank among the many innovations associated with this development.

These platforms typically feature two primary modules, cloud-connected monitoring devices and personal protective equipment (PPE). These wearable assets, which include gas detectors, hardhats, and fall protection can monitor workers and the environments in which they function and collect real-time insights. The information was then sent to centralized software portals, where EHS leaders can monitor conditions on the ground and gather historical data to improve safety.

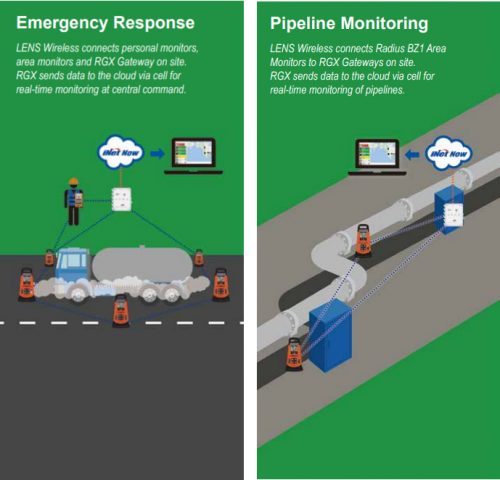

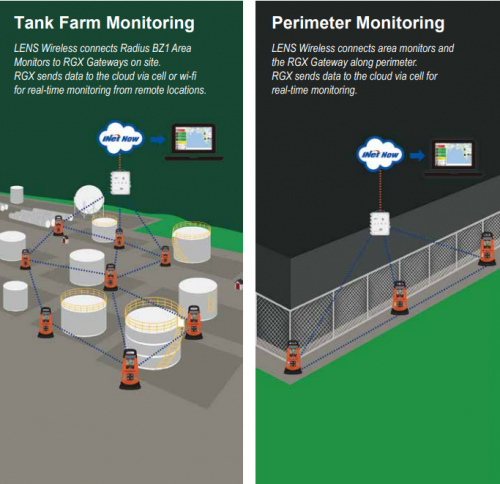

Connected safety software function effectively in multiple settings, including the harsh industrial environments found at manufacturing plants, mines, oil and gas production sites, and hazardous material storage locations.

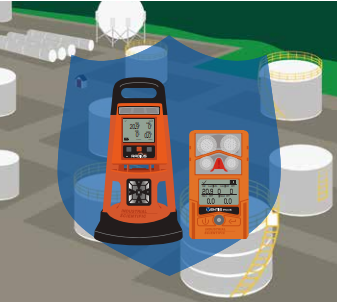

Personal Gas and Area Monitoring

With the Ventis Pro5 Personal Gas Monitor and Radius BZ1 Area Monitor, you have the flexibility to choose how you want your teams to connect. You can opt for peer-to-peer alarm sharing, personal monitor to area monitor connectivity, or remote live monitoring.

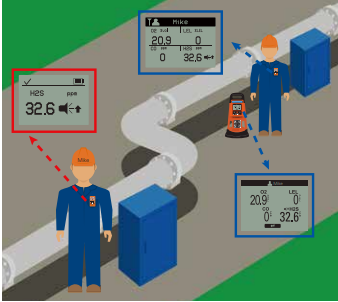

Team and Site Based Safety

Give workers insight to their surroundings by sharing alarms and notifications between gas monitors.

Application: Teams working in confined spaces can use connected gas detectors to automatically alert attendants when conditions become unsafe

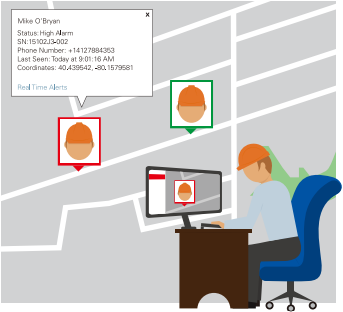

Manage Safety and Productivity

Get data out of any situation and increase productivity by knowing where your workers are and what dangers they may encounter.

Application: Safety managers can use connected gas monitors to send muster messages to all employees in an evacuation zone .Industrial hygienists can remotely monitor fence lines after a gas explosion to minimize the impact on neighboring communities.

Contact Person: Pankaj Prajapati, Country Manager, India

Telephone : +91 9967592602, +91 9824289645

Fax No :+65-65617787

Email : [email protected], [email protected]

Website :Click to visit website